The DeSimone laboratory aims to develop innovative, interdisciplinary solutions to complex problems centered around advanced polymer 3D fabrication methods. Through our Chemical Engineering and Materials Science focus area, we are pursuing new capabilities in digital 3D printing, as well as the synthesis of new polymers for use in advanced additive technologies. We aim to employ these advances through our Translational Medicine focus area, including to investigate new vaccine platforms, enhanced drug delivery approaches, and improved medical devices for numerous conditions, with an initial major focus in pediatrics. Complementing these research areas, our group has a third focus in Entrepreneurship, Digital Transformation, and Manufacturing.

High-Resolution Additive Manufacturing

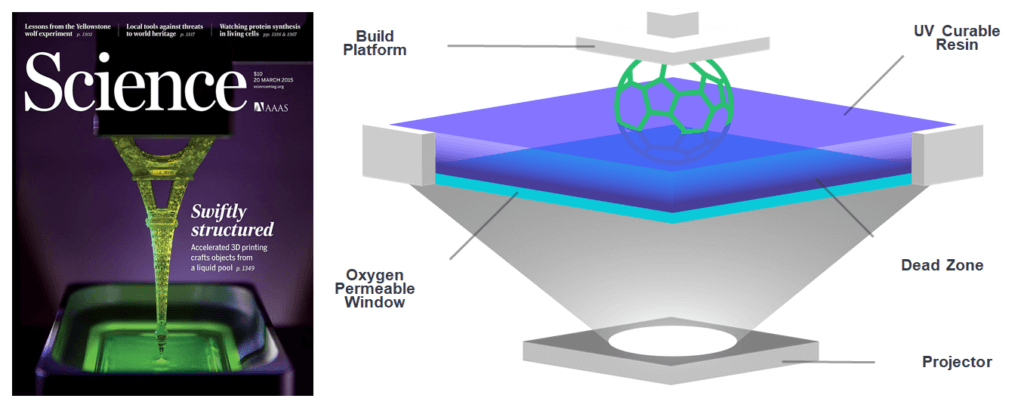

Building on previous advances by the DeSimone lab related to the continuous liquid interface production (CLIP) polymer 3D printing technology (Science, 2015), we are currently pursuing the development of new digital 3D printing capabilities. We have recently developed a 3D printer with 1.5-micron projection optics (high-resolution CLIP), which uses light and oxygen to rapidly produce structures and devices from a wide range of biomaterials with geometries down to single-digit micron resolution, and at a print speed that is 105 times faster than commercially available high-resolution direct write printers (Science Advances, 2022).

Additionally, we have developed a technology referred to as “injection CLIP” (iCLIP), which enables the generation of negative spaces (channels, void spaces, and chambers) by preventing UV overcuring in the z-axis which plagues traditional UV-based 3D printing technologies (Science Advances, 2022). We are currently leveraging this technique to fabricate complex microfluidic networks for biomedical diagnostics and treatment. We have also established a scalable, high-resolution technique referred to as roll-to-roll continuous liquid interface production (r2rCLIP), for the production of microscopic particles with permutable, intricate designs which enable direct integration within biomedical, analytical, and advanced materials applications (Nature, 2024).

We are applying these novel additive manufacturing techniques to address fundamental challenges in developing multi-scale biomedical devices, and are continuing to explore novel methods for multi-material 3D printing.

Translational Medicine

In the DeSimone lab, we are extremely motivated to leverage both new and existing 3D printing techniques and polymer materials capabilities to improve human health. Advances in print resolution and speed allow for the fabrication of complex structures with applications in drug delivery, diagnostics, and regenerative medicine. For example, we have developed novel microarray patches (MAPs), wherein novel 3D printing capabilities have enabled the production of new classes of lattice MAPs and dynamic MAPs (JACS Au, 2022). These systems can deliver both solid state and liquid cargos, and are also capable of sampling interstitial fluid (ISF) for minimally invasive biomarker detection. In conjunction with our partners, our goal is to create a platform approach that is readily adaptable to accommodate any suite of antigen(s) and adjuvants(s), that triggers a robust and durable immune response, that reduces or eliminates reliance on a cold chain, and that provides advantages for simplifying vaccine administration.

In the DeSimone lab, we are extremely motivated to leverage both new and existing 3D printing techniques and polymer materials capabilities to improve human health. Advances in print resolution and speed allow for the fabrication of complex structures with applications in drug delivery, diagnostics, and regenerative medicine. For example, we have developed novel microarray patches (MAPs), wherein novel 3D printing capabilities have enabled the production of new classes of lattice MAPs and dynamic MAPs (JACS Au, 2022). These systems can deliver both solid state and liquid cargos, and are also capable of sampling interstitial fluid (ISF) for minimally invasive biomarker detection. In conjunction with our partners, our goal is to create a platform approach that is readily adaptable to accommodate any suite of antigen(s) and adjuvants(s), that triggers a robust and durable immune response, that reduces or eliminates reliance on a cold chain, and that provides advantages for simplifying vaccine administration.

Additionally, we are establishing a 3D printed platform for organ-specific iontophoresis for in situ CAR-T cell therapy, to enhance CAR-T cell production, trafficking, and tumor infiltration while simultaneously reducing systemic toxicity and dosing frequency. We also utilize 3D printing to facilitate the generation of intricate vasculature networks, which can be used to make a viable and functional ventricle bioreactor model to mimic certain aspects of the heart’s functionality, providing insights into tissue engineering, drug testing, and regenerative medicine applications. Finally, we are developing an alternative mRNA delivery platform referred to as Targeted Reductively Cleavable Acrylate-based Inverse Microemulsion Nanogels (TRAINs), which overcomes limitations of traditional lipid nanoparticle approaches. This platform has demonstrated low toxicity, and enhanced specificity, cellular uptake, and gene delivery efficiency.

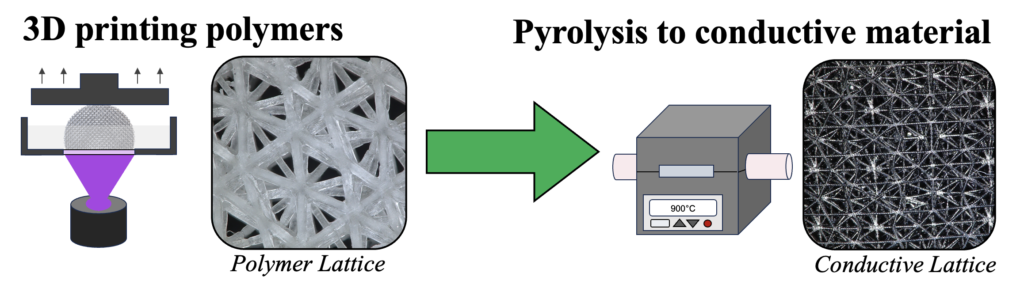

Sustainable Energy and Electrification

Entrepreneurship, Digital Transformation, and Manufacturing

Complementing and augmenting our lab’s work in translational medicine, members of the DeSimone group are exposed not only to potential entrepreneurial opportunities as they emerge from our lab’s research advances, but also to key concepts in entrepreneurship through Prof. DeSimone’s affiliation and teaching through the Stanford Graduate School of Business. In addition to translating university-based research advances to the market to achieve practical impact, subjects of particular interest within entrepreneurship include peer accountability and diversity, equity, and inclusion within companies and on company boards.

Moreover, as digital 3D fabrication technologies become more commonly utilized—not just for prototyping but for real product manufacturing—this emergent shift provides an opportunity to examine topics such as supply chain disruption and modernization, as well as strategies toward achieving a circular economy.

Image credit: The circular economy concept (http://www.wrap.org.uk/content/wrap-and-circular-economy)