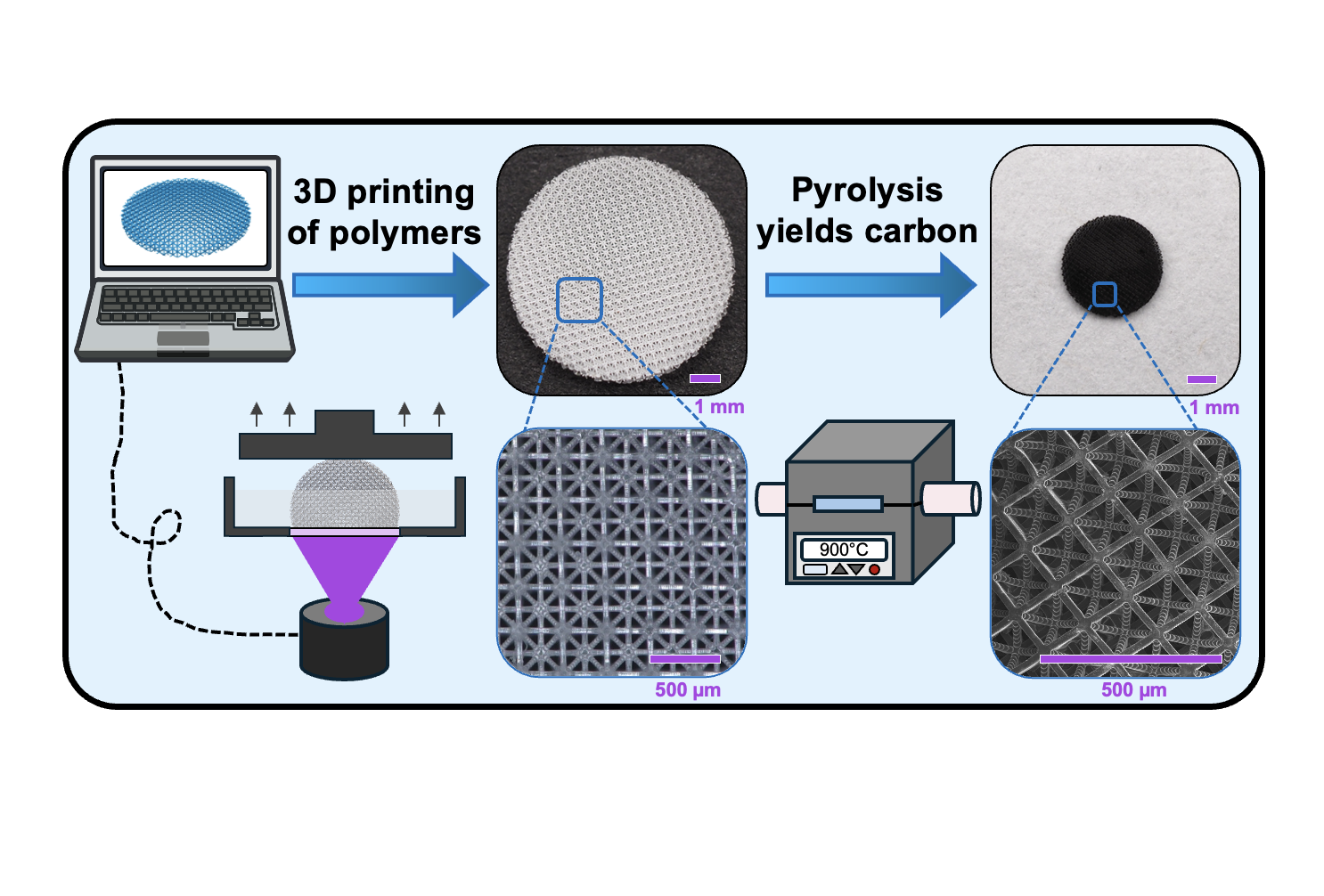

Perspective on the intersection of 3D printing and pyrolysis for production of carbon structures for sustainable energy

Congratulations to chemical engineering PhD candidate, Philip R. Onffroy, on the recent publication of his JACS Au perspective paper! His paper, titled ‘Opportunities at the Intersection of 3D Printed Polymers and Pyrolysis for the Microfabrication of Carbon-Based Energy Materials', outlines the transformative potential of integrating 3D printing with high temperature pyrolysis for creating high-performance carbon materials for sustainable energy applications. This perspective highlights the critical roles of polymer resin chemistry, advanced photopolymerization additive manufacturing methods, and precise pyrolysis conditions in determining the structural and functional properties of carbon microarchitectures. This approach enables scalable fabrication of high-resolution carbon structures with applications ranging from energy storage to catalysis, showcasing its promise in advancing the clean energy transition. Other co-authors on this paper include U.C. Merced collaborators Samuel Chiovoloni, Han Lin Kuo, and Prof. Jennifer Lu along with DeSimone Lab members Max A. Saccone and Prof. Joseph M. DeSimone.

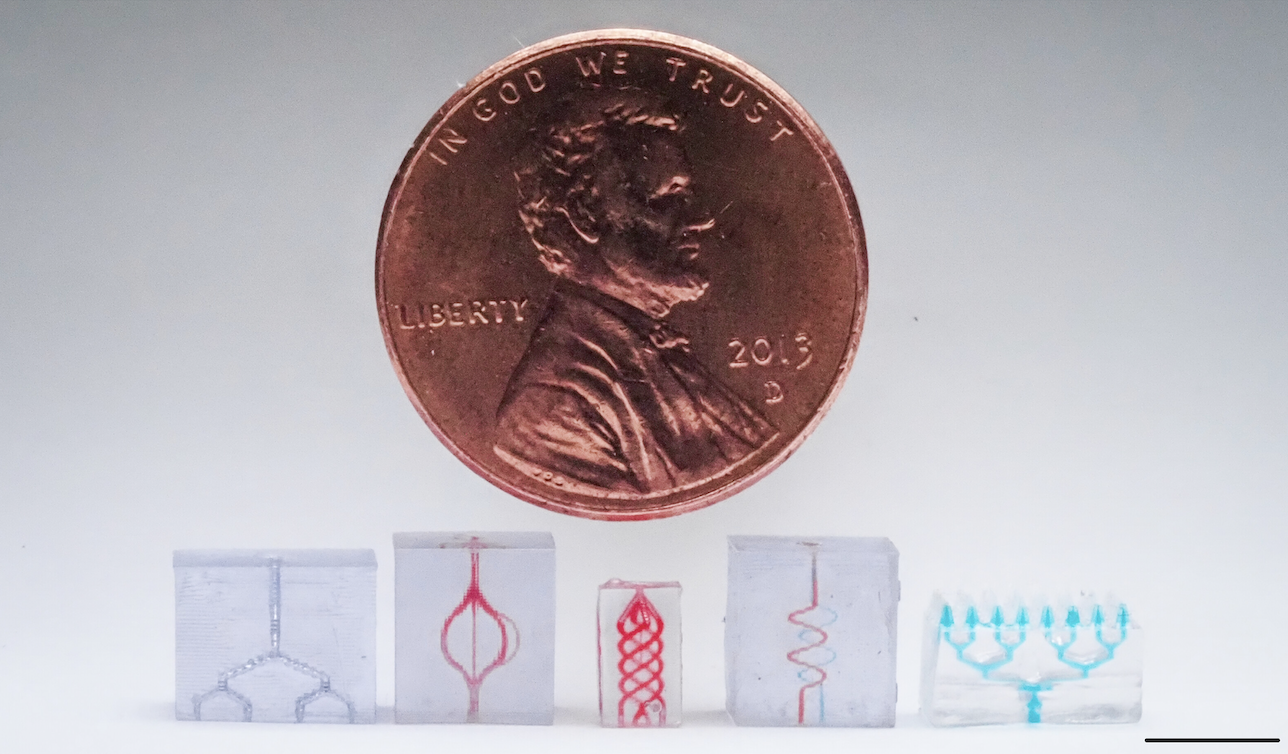

Revolutionary high resolution negative spaces and micro channels generated via controlled fluid mechanics

Congratulations to chemical engineering PhD candidate, Ian A. Coates, on the recent publication of his PNAS paper! His paper, titled ‘High-resolution stereolithography: Negative spaces enabled by control of fluid mechanics', highlights the use of high-resolution injection continuous liquid interface production (iCLIP) to addresses the long-standing issue of overcuring in stereolithographic 3D printing by enabling precise control of resin flow. This innovation allows for the fabrication of microscale negative spaces, such as microchannels, with unparalleled resolution and material flexibility. The work demonstrates potential applications in microfluidics, biomedical devices, and microelectromechanical systems, showcasing the transformative impact of iCLIP on the field of advanced manufacturing. Other Stanford co-authors and DeSimone Lab members on this paper include William Pan, Max A. Saccone, Gabriel Lipkowitz, Dan Ilyin, Madison M. Driskill, Maria T. Dulay, Curtis W. Frank, Eric S. G. Shaqfeh, and Prof. Joseph M. DeSimone.

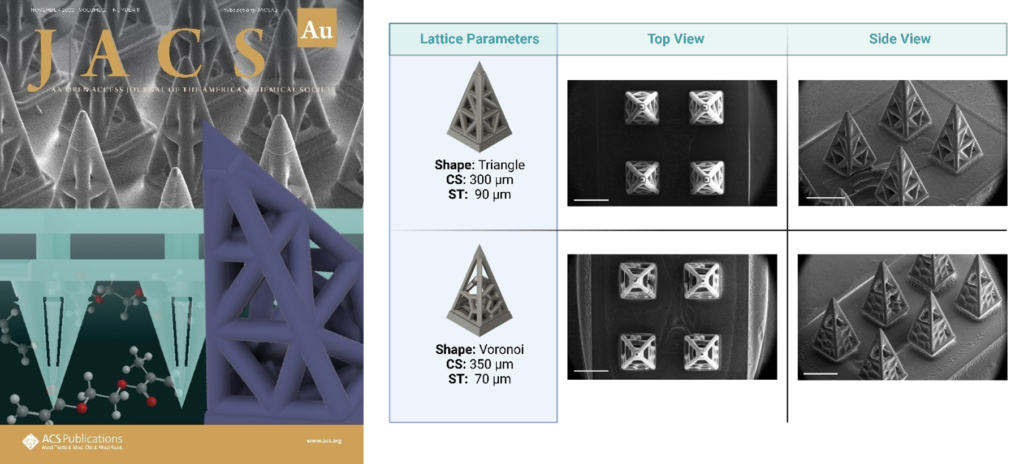

3D-printed lattice microneedle array patches (L-MAPs) enable tunable and versatile intradermal drug delivery

Congratulations to bioengineering PhD candidate, Netra Unni Rajesh, on the recent publication of her Advanced Materials paper! Her paper, titled ‘3D-Printed Latticed Microneedle Array Patches for Tunable and Versatile Intradermal Delivery', introduces 3D-printed latticed microneedle array patches (L-MAPs) as a versatile platform for next generation painless intradermal drug delivery. By leveraging innovative lattice needle geometries and advanced fabrication techniques, L-MAPs enable efficient delivery of both solid and liquid therapeutics, including small molecules, proteins, and mRNA. This work demonstrates enhanced cargo loading, customizable release profiles, and potential applications in vaccines and drug delivery. Other Stanford co-authors and DeSimone Lab members on this paper include Jihyun (Luna) Hwang, Yue Xu, Max A. Saccone, Andy H. Hung, Rose A.S. Hernandez, Ian A. Coates, Madison M. Driskill, Maria T. Dulay, Gunilla B. Jacobson, Shaomin Tian, Jillian L. Perry, and Prof. Joseph M. DeSimone.

New perspective "Growing three-dimensional objects with light" overviews current state of vat photopolymerization

Congratulations to mechanical engineering PhD candidate, Gabriel Lipkowitz, and chemical engineering postdoc, Max A. Saccone, on their recent publication of their PNAS perspective paper! Their paper, titled ‘Growing three-dimensional objects with light’, overviews the recent advances, capabilities, and exciting new horizons for the additive manufacturing category of vat photopolymerization (VP). As part of this perspective, they enlist the help of Matthew Panzer from Carbon, Inc. to visualize the fascinating effect that an oxygen-rich dead zone in continuous liquid interface production (CLIP) VP has on enabling high speed, continuous VP 3D printing. The VP technologies outlined in their paper are revolutionizing scalable production of non-moldable high resolution advanced structures used throughout the DeSimone lab's research projects. Other Stanford co-authors and DeSimone Lab members on this paper include Ian A. Coates, Kaiwen Hsiao, Daniel Ilyin, Jason M. Kronenfeld, John R. Tumbleston, Eric S. G. Shaqfeh, and Prof. Joseph M. DeSimone.

High resolution roll-to-roll 3D printing enables daily production of 1 million microscale particles

Congratulations to chemistry PhD candidate, Jason Kronenfeld, on the recent publication of his Nature paper on Pi Day 2024! His paper, titled ‘Roll-to-roll, high-resolution 3D printing of shape-specific particles’, demonstrates the use of roll-to-roll continuous liquid interface production (r2rCLIP) with single-digit, micron-resolution optics. This technique addresses previous particle fabrication shortcomings, enabling the rapidly permutable fabrication and harvesting of shape-specific particles from a variety of materials and with complex geometries. This enables production of micron-scale shapes, ranging from moldable to non-moldable, at speeds of up to 1,000,000 particles per day. This “digital dust” enables direct integration within biomedical, analytical, and advanced materials applications, ranging from hard (ceramics) to soft (hydrogels). Other Stanford co-authors and DeSimone Lab members on this paper include Lukas Rother, Max A. Saccone, Maria T. Dulay, and Prof. Joseph M. DeSimone.

Lattice Designs Honored at Stanford Art of Science Exhibit and Ontario Science Centre

DeSimone Lab graduate students Philip Onffroy and Netra Unni Rajesh recently had their work selected as finalists in the "Art of Science" exhibit curated by the Stanford Materials Research Society featuring pieces that demonstrate the intersection of art and science. Philip's piece is an image displaying a metallized Voronoi polymer lattice generated via CLIP 3D printing followed by Nickel deposition for use in conductive polymer applications, such as in battery electrodes. Netra's submission is an image showcasing the scale of CLIP 3D-printed lattice microarray patches developed in the lab. The needle geometries aren't visible to the naked eye at this scale; however, Netra used her talents in nail art to showcase the complex, lattice structures of the needles on her nails. We are also excited to share that Netra's image is also currently being featured at the Ontario Science Centre, Canada, in an exhibit titled "Vaccines without Needles." This piece looks at educating visitors on novel, cutting-edge technologies, to make painless vaccination a reality!

3D printing expands design space for transdermal applications

Congratulations to bioengineering PhD candidate, Netra Unni Rajesh, on the recent publication of her JACS Au Perspectives article! Her paper, titled ‘3D-Printed Microarray Patches (MAPs) for Transdermal Applications’, was featured on the cover and published last month. The paper provides a comprehensive review of conventional methods used to produce MAPs and introduces two novel classes of MAPs, only made possible by high resolution CLIP. Latticed MAPs (L-MAPs) can be used to deliver solid and liquid state formulations while dynamic MAPs (D-MAPs) can interact with the skin to alter properties. Other Stanford co-authors and DeSimone Lab members on this paper include Ian Coates, Madison M. Driskill, Maria T. Dulay, Kaiwen Hsiao, Dan Ilyin, Gunilla B. Jacobson, Jean Won Kwak, Micah Lawrence, Jillian Perry, Cooper O. Shea, Shaomin Tian, and Prof. Joseph M. DeSimone.